As young farmers of the sea, we are shocked by how much plastic it takes to rear our oysters and seaweed!

Degraded plastic fiber pollution from conventional aquaculture gear and customary materials contributes to the pollution of marine environments. Plastics cause harm to marine organisms at multiple scales through habitat damage and decreased water quality. This may cause a deleterious effect where we are growing food! As our plastic ropes fray, their tiny shards of petri-chemicals and the pollutants bound to them become a part of the bodies of shellfish we grow. Buoys and other gear introduce yet more plastics into our ocean waters. How can we prevent this?

One of our key ongoing "action research" projects at Seaweed Commons is "Alternatives to Plastics in Aquaculture," a series of participatory experiments in non-plastic materials for aquaculture. As beginning and lifelong aquaculturists in love with the ocean and all the life they contain, we seek to maintain a high-quality cultivation environment. One major way to do this is reducing the use of plastics on and in the water. New aquaculture leases in Maine have more than quadrupled in the past 5 years, most of them at a small enough scale to consider using alternative gear (which will most likely be more costly) to the almost 100% plastic options that are currently mainstream. It would be a huge step to create and establish workable alternatives for new or expanding farmers.

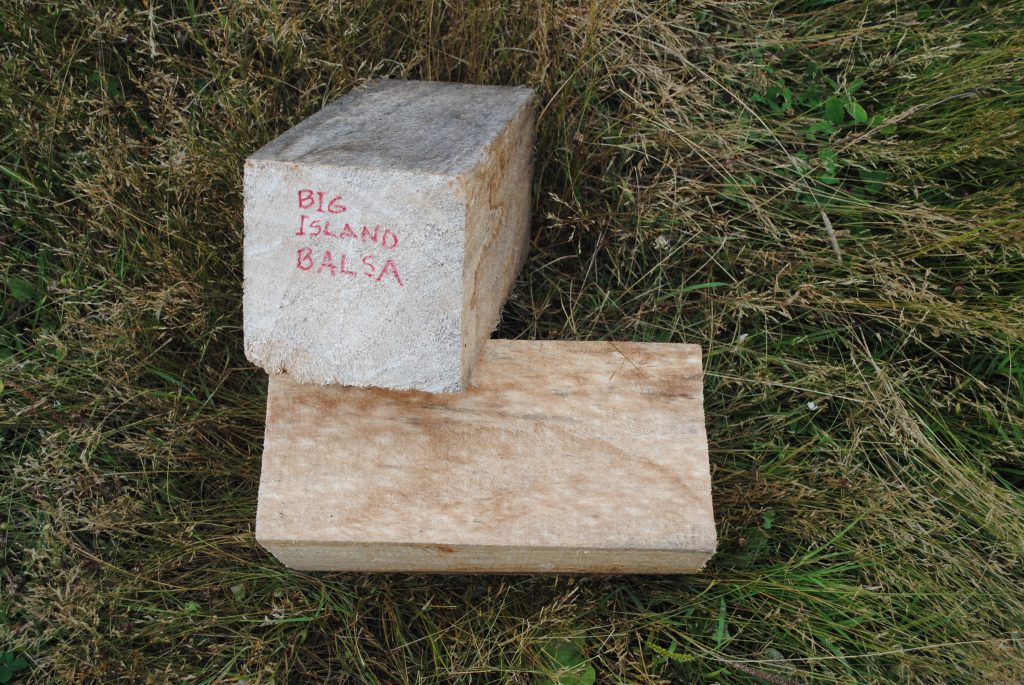

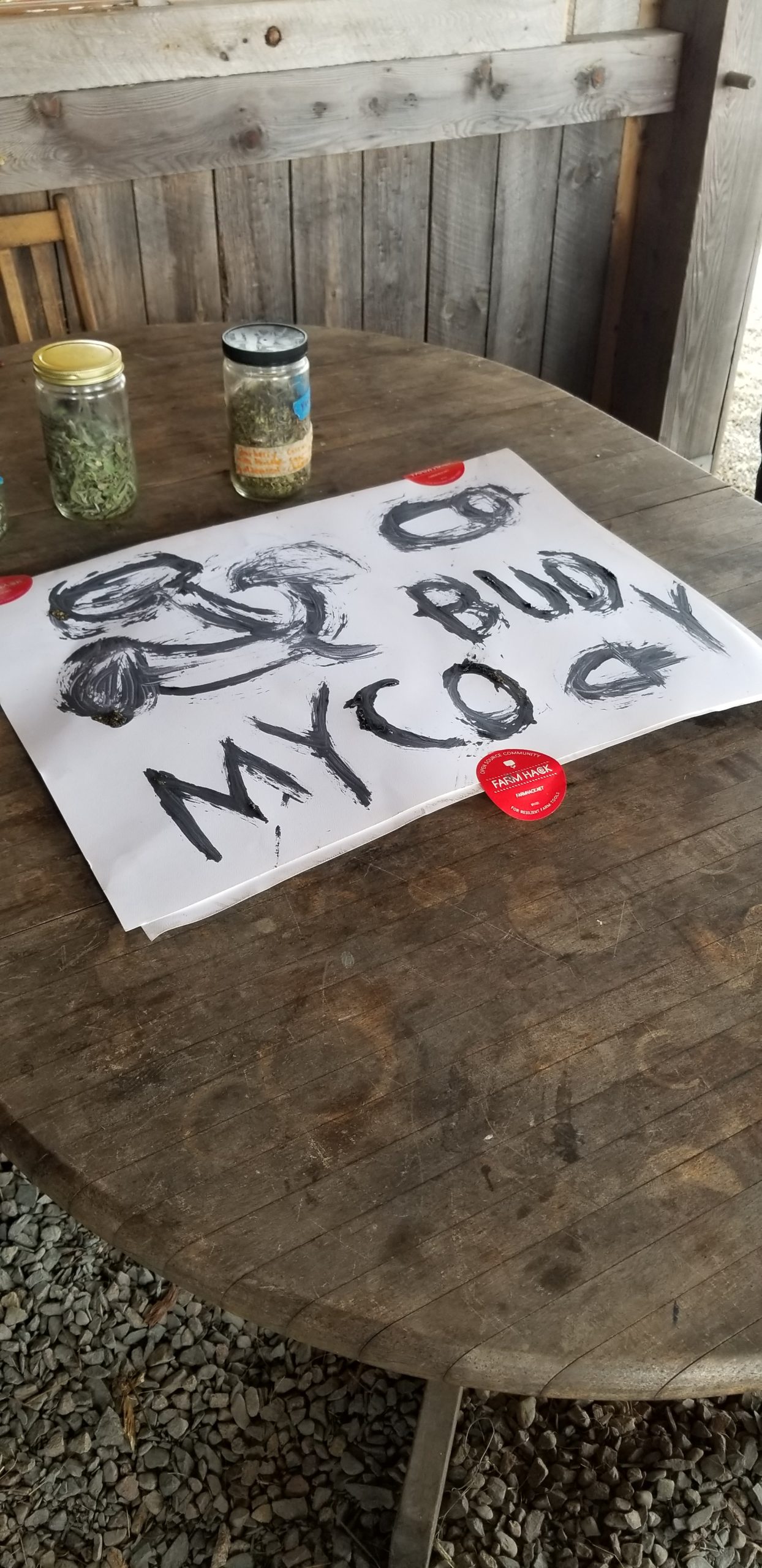

This project was first funded by NESARE in 2020 to support the partnership of Smithereen Farm and Long Cove Sea Farm in exploring, testing, examining and discerning how traditional (and non-traditional) marine materials, including hemp, cork, coir, cedar, pine tar, and mycelium, can be used in the construction of lines, floats, and oyster cages. Now we are working with mycologist Sue Van Hook to learn about and build a biodegradable myco-buoy that you put into your cages in the spring, and take out when you sink your cages in the fall.

Seaweed Commons is working with mycologist Sue Van Hook to create a biodegradable myco-buoy that you put into your cages in the spring, and take out when you sink your cages in the fall.

While working as the Mycologist at Ecovative Design from 2007-2016 MycoBuoys Founder, Sue Van Hook, discovered that their mushroom biocomposite material was buoyant. At first, she observed that mycelium grown in liquid culture without agitation formed a thin skin atop the surface. In addition, she watched small droplets of water roll around the surface of the skin without losing their shape. Her experiments revealed properties of buoyancy and repellency being exhibited by the mycelium.

We hope that in the near future that we could contribute as advocates, stakeholders, and co-designers of our evolving regulatory system— where the best practices we cherish in our sector are protected. We want to participate in locally owned, conservation minded, suitably sited and, hopefully a truly 'sustainable aquaculture.’

It may be that we can create a set of standards or a label that would help small producers like ourselves compete in markets that already privilege large-scale operations.

See “ Aquaculture and the Plastic Problem" - Edible Magazine, and Mushroom Buoys - Bangor Daily News to learn more. If you want to join our research and collective self-educating, email [email protected] with questions, ideas, or to find ways to get involved!

In partnership with Long Cove Sea Farms.